Sterile vs. Non-Sterile Compounding: What Pharmacy Techs Really Need to Know

Quick Summary

|

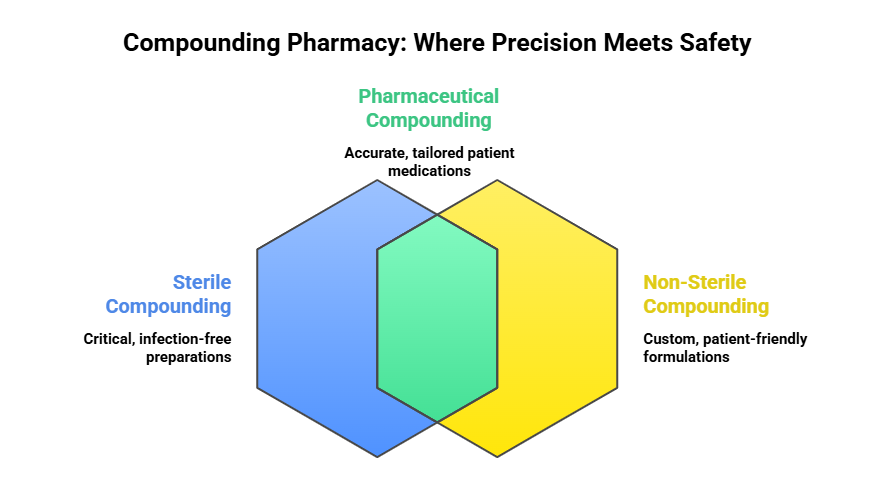

In the world of pharmacy, compounding isn’t just a niche skill—it’s a critical part of personalized patient care. Whether it’s preparing a sterile IV solution for surgery or customizing a flavored syrup for a child, pharmacy technicians play a hands-on role in improving outcomes.

As personalized medicine grows, so does the demand for trained professionals who can safely and accurately prepare medications. In fact, the FDA estimates that millions of compounded drugs are dispensed in the U.S. each year, with 7,500 pharmacies engaged in compounding practices.

Understanding sterile vs. non-sterile compounding is no longer optional—it’s essential.

What Is Compounding in Pharmacy?

You know those meds you can’t find on a shelf—because they’re too rare, too specific, or too personal? That’s where compounding steps in.

Compounding is the process of mixing, altering, or customizing medications to meet unique patient needs. Think of it as pharmaceutical problem-solving in real time.

According to a study, over 30 million compounded prescriptions are dispensed each year in the U.S. Source.

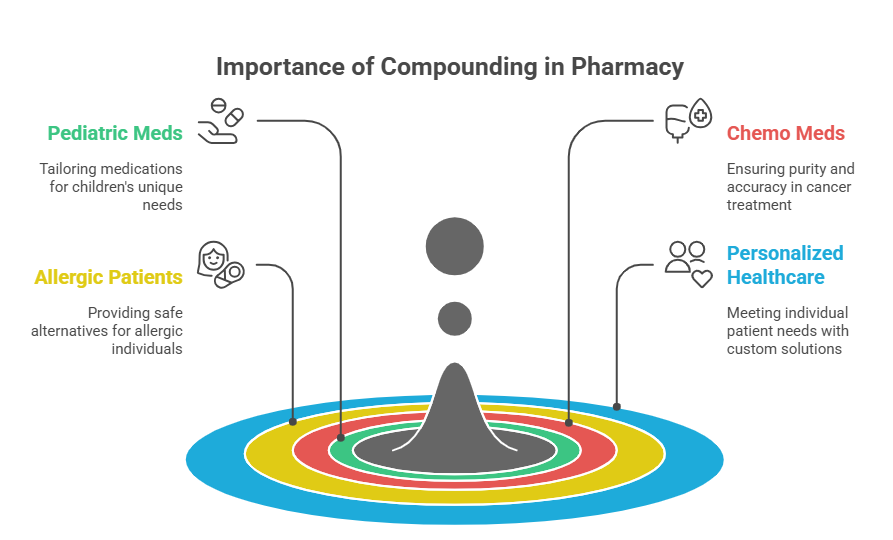

Why is Compounding in Pharmacy so Important?

Compounding is precision under pressure. You’re not just scooping powder into capsules. You’re ensuring a preemie in the NICU survives, or that a chemo patient gets exact IV dosing with no contamination. It’s real. It’s personal. And it matters.

- Pediatric meds often need lower doses and different formats (like syrups or lollipops).

- Chemo meds can’t afford cross-contamination.

- Allergic patients need compound-only alternatives.

- One-size-fits-all doesn’t exist in healthcare anymore—and that’s where compounding wins.

Why Demand Is Booming

- Personalized medicine is now the norm, not the exception.

- Patients are asking for flavor-customized, allergen-free, age-appropriate meds.

- Pharmacies—especially compounding and hospital ones—need certified techs who can handle it all.

Imagine this: one tech prepares a grape-flavored pain reliever for a child, the other fills a chemo IV bag for surgery. Both are vital—but one slip-up is far more dangerous.

Sterile Compounding: High Stakes, No Margin for Error

- Used for IVs, injections, surgical meds, and eye drops

- Must be prepared in ISO Class 5 cleanrooms

- Follows strict USP <797> standards

- Involves sterile gloves, filtered airflow, gowning, and aseptic technique

A mistake here isn’t a typo—it’s an infection risk.

Non-Sterile Compounding: Custom, but Lower Risk

- Used for capsules, creams, syrups, flavored meds

- Done in a clean area, no sterile airflow required

- Focus is on accuracy, taste, and formulation stability

Governed by USP <795>

This is where creativity meets chemistry—still technical, but not life-threatening.

Sterile vs. Non-Sterile Compounding

| Feature | Sterile Compounding | Non-Sterile Compounding |

| Purpose | IVs, injections, ophthalmics | Topicals, capsules, oral meds |

| Risk Level | High – any contamination can be fatal | Moderate – improper mix = inefficacy |

| Environment | ISO Class 5 cleanroom | Ventilated, sanitized prep station |

| Protocol | Gowning, gloving, sterile tools | PPE, sanitation, accurate formulation |

| Standards | USP <797> | USP <795> |

| Settings | Hospitals, oncology, surgical centers | Retail, dermatology, compounding labs |

When Is Sterile Compounding Necessary?

When the medication is going straight into the bloodstream—or into vulnerable tissue—clean isn’t enough. It has to be sterile.

Common High-Risk Use Cases

High-Risk Situations You’ll See on the Job:

- NICU medications for premature infants

- Chemotherapy agents requiring ultra-clean delivery

- Surgical IV antibiotics when infection is fatal

- Total Parenteral Nutrition (TPN) for patients who can’t eat

Employers will expect you to know how to navigate these situations—and prove it during interviews.

Why It Matters to Employers

- Many roles require an understanding of USP <797> compliance

- Employers assess your ability to handle life-critical medications

- Certification shows you’re prepared for sterile environments

When is Non-Sterile Compounding Used?

Just because a drug isn’t injected doesn’t mean it’s simple. Non-sterile compounding is vital for:

- Hormone therapies tailored to individual needs

- Pediatric medications with kid-friendly flavors

- Veterinary meds for dosing by species/weight

- Topical treatments like anti-fungal creams and gels

Certifications That Employers Trust

These certifications don’t just pad your resume—they qualify you for specialized roles in healthcare.

Sterile (IV) Compounding – 40 Clock Hours at CCI Training

- Learn aseptic technique, sterile prep, gowning, needle handling, and laminar flow hood usage

- Built to align with protocols used in hospitals and infusion centers

- Equips you with foundational skills required for USP <797> environments

Non-Sterile Compounding – 40 Clock Hours at CCI Training

- Hands-on experience with capsules, PLO gels, medicated lollipops, creams, and flavorings

- Emphasis on formulation accuracy, patient-specific customization, and USP <795> compliance

- Ideal preparation before sitting for national pharmacy tech exams

CCI Training offers hands-on courses in sterile and non-sterile compounding, preparing students for high-demand roles in hospitals and pharmacies while ensuring compliance with USP <797> and <795> standards.

Note: Completion certificates from CCI Training demonstrate hands-on training, which can strengthen your eligibility for PTCB or ExCPT certification and boost your job-readiness in compounding roles.

Inside the Lab: What You’ll Actually Do

Compounding certification isn’t just textbook learning. You’ll get hands-on experience with:

- Preparing sterile solutions in laminar flow hoods

- Weighing powders and combining active ingredients

- Labeling, logging, and checking for safety compliance

- Following compounding logs and checklists used in real pharmacies

Career Path After Certification

Whether you’re pivoting careers or upskilling, compounding can open the door to roles like:

| Job Title | Where You Might Work |

| Compounding Pharmacy Technician | Independent or specialty compounding pharmacies |

| Hospital Pharmacy Technician | Hospitals and infusion clinics |

| Home Infusion Support Technician | Home health care agencies |

| Sterile Compounding Specialist | Surgical centers or oncology units |

And yes—you can get there with a certification-backed foundation like CCI Training’s.

Final Words

Whether you’re drawn to the meticulous precision of sterile compounding or the hands-on creativity of non-sterile preparations, one thing’s clear—compounding is where pharmacy makes its biggest human impact.

With certifications in hand, you’ll step into the workforce with confidence, clarity, and a deep understanding of how to help patients when mass-produced meds just won’t cut it.

Program Offered

- Pharmacy Technician Training

- Online Medical Assistant

- Medical Billing and Coding Specialist Program

- Cloud Computing Technician Training

- Computer Network Technician

- Business and Accounting

- Radiology Technician Training

- Medical Assistant Program

- Computer Support Technician

- Cybersecurity Program

- Virtual Assistant Training

This article is written by

Share this article

Quick Summary

|

What Is Compounding in Pharmacy?

You know those meds you can’t find on a shelf—because they’re too rare, too specific, or too personal? That’s where compounding steps in. Compounding is the process of mixing, altering, or customizing medications to meet unique patient needs. Think of it as pharmaceutical problem-solving in real time. According to a study, over 30 million compounded prescriptions are dispensed each year in the U.S. Source.Why is Compounding in Pharmacy so Important?

Compounding is precision under pressure. You’re not just scooping powder into capsules. You’re ensuring a preemie in the NICU survives, or that a chemo patient gets exact IV dosing with no contamination. It’s real. It’s personal. And it matters.

Compounding is precision under pressure. You’re not just scooping powder into capsules. You’re ensuring a preemie in the NICU survives, or that a chemo patient gets exact IV dosing with no contamination. It’s real. It’s personal. And it matters.

- Pediatric meds often need lower doses and different formats (like syrups or lollipops).

- Chemo meds can’t afford cross-contamination.

- Allergic patients need compound-only alternatives.

- One-size-fits-all doesn’t exist in healthcare anymore—and that’s where compounding wins.

Why Demand Is Booming

- Personalized medicine is now the norm, not the exception.

- Patients are asking for flavor-customized, allergen-free, age-appropriate meds.

- Pharmacies—especially compounding and hospital ones—need certified techs who can handle it all.

Sterile Compounding: High Stakes, No Margin for Error

- Used for IVs, injections, surgical meds, and eye drops

- Must be prepared in ISO Class 5 cleanrooms

- Follows strict USP <797> standards

- Involves sterile gloves, filtered airflow, gowning, and aseptic technique

Non-Sterile Compounding: Custom, but Lower Risk

- Used for capsules, creams, syrups, flavored meds

- Done in a clean area, no sterile airflow required

- Focus is on accuracy, taste, and formulation stability Governed by USP <795>

Sterile vs. Non-Sterile Compounding

| Feature | Sterile Compounding | Non-Sterile Compounding |

| Purpose | IVs, injections, ophthalmics | Topicals, capsules, oral meds |

| Risk Level | High – any contamination can be fatal | Moderate – improper mix = inefficacy |

| Environment | ISO Class 5 cleanroom | Ventilated, sanitized prep station |

| Protocol | Gowning, gloving, sterile tools | PPE, sanitation, accurate formulation |

| Standards | USP <797> | USP <795> |

| Settings | Hospitals, oncology, surgical centers | Retail, dermatology, compounding labs |

When Is Sterile Compounding Necessary?

When the medication is going straight into the bloodstream—or into vulnerable tissue—clean isn’t enough. It has to be sterile.Common High-Risk Use Cases

High-Risk Situations You’ll See on the Job:- NICU medications for premature infants

- Chemotherapy agents requiring ultra-clean delivery

- Surgical IV antibiotics when infection is fatal

- Total Parenteral Nutrition (TPN) for patients who can’t eat

Why It Matters to Employers

- Many roles require an understanding of USP <797> compliance

- Employers assess your ability to handle life-critical medications

- Certification shows you’re prepared for sterile environments

When is Non-Sterile Compounding Used?

Just because a drug isn’t injected doesn’t mean it’s simple. Non-sterile compounding is vital for:- Hormone therapies tailored to individual needs

- Pediatric medications with kid-friendly flavors

- Veterinary meds for dosing by species/weight

- Topical treatments like anti-fungal creams and gels

Certifications That Employers Trust

These certifications don’t just pad your resume—they qualify you for specialized roles in healthcare.Sterile (IV) Compounding – 40 Clock Hours at CCI Training

- Learn aseptic technique, sterile prep, gowning, needle handling, and laminar flow hood usage

- Built to align with protocols used in hospitals and infusion centers

- Equips you with foundational skills required for USP <797> environments

Non-Sterile Compounding – 40 Clock Hours at CCI Training

- Hands-on experience with capsules, PLO gels, medicated lollipops, creams, and flavorings

- Emphasis on formulation accuracy, patient-specific customization, and USP <795> compliance

- Ideal preparation before sitting for national pharmacy tech exams

Inside the Lab: What You’ll Actually Do

Compounding certification isn’t just textbook learning. You’ll get hands-on experience with:- Preparing sterile solutions in laminar flow hoods

- Weighing powders and combining active ingredients

- Labeling, logging, and checking for safety compliance

- Following compounding logs and checklists used in real pharmacies

Career Path After Certification

Whether you’re pivoting careers or upskilling, compounding can open the door to roles like:| Job Title | Where You Might Work |

| Compounding Pharmacy Technician | Independent or specialty compounding pharmacies |

| Hospital Pharmacy Technician | Hospitals and infusion clinics |

| Home Infusion Support Technician | Home health care agencies |

| Sterile Compounding Specialist | Surgical centers or oncology units |

Final Words

Whether you’re drawn to the meticulous precision of sterile compounding or the hands-on creativity of non-sterile preparations, one thing’s clear—compounding is where pharmacy makes its biggest human impact. With certifications in hand, you’ll step into the workforce with confidence, clarity, and a deep understanding of how to help patients when mass-produced meds just won’t cut it.Program Offered

- Pharmacy Technician Training

- Online Medical Assistant

- Medical Billing and Coding Specialist Program

- Cloud Computing Technician Training

- Computer Network Technician

- Business and Accounting

- Radiology Technician Training

- Medical Assistant Program

- Computer Support Technician

- Cybersecurity Program

- Virtual Assistant Training

This article is written by

Share this article

Program Offered

- Pharmacy Technician Training

- Online Medical Assistant

- Medical Billing and Coding Specialist Program

- Cloud Computing Technician Training

- Computer Network Technician

- Business and Accounting

- Radiology Technician Training

- Medical Assistant Program

- Computer Support Technician

- Cybersecurity Program

- Virtual Assistant Training

This article is written by

Share this article

Frequently Asked Questions FAQ's

What’s the difference between sterile and non-sterile compounding?

Sterile compounding is for high-risk meds (like IVs), requiring total sterility. Non-sterile is for oral/topical forms and focuses on formulation accuracy.

Why is sterile compounding necessary?

Because some meds go directly into the bloodstream, contamination can cause infections or worse.

Can pharmacy techs do compounding?

Yes, with proper training and certification—especially those who complete USP <795>/<797> aligned programs.

Is non-sterile compounding easier?

It’s less regulated but still demands precision. A wrong dose can still harm a patient.

Can pharmacy techs prepare non-sterile compounds?

Absolutely. And with a non-sterile compounding certification, you’re instantly more employable.

How to become a compounding pharmacy technician?

To become a compounding pharmacy technician, complete a Pharmacy Technician Training program with sterile/non-sterile certification like those offered by CCI Training Center. Then, earn national certification (PTCB/ExCPT) and gain hands-on experience.

Related Articles

CCI Training Center Proudly Completes

41 Years in Career Training Services